Offsite testing

Hydrogen and natural gas have different properties that could affect both operational and material aspects of our network.

To understand what changes were required, we developed a suite of testing programmes with The Welding Institute (TWI) in Cambridge, and DNV in Spadeadam, Cumbria. These laboratory-scale and full-scale tests allowed us to expand our knowledge of how a hydrogen LTS would differ from our current natural gas LTS.

Some of our offsite testing is still ongoing and will be completed by March 2026.

Testing at TWI

At TWI, a laboratory mechanical testing programme on three different representative LTS pipes is underway, including Grangemouth to Granton pipeline material. These tests allow us to understand how the mechanical properties of pipeline material and welds are affected by exposure to hydrogen.

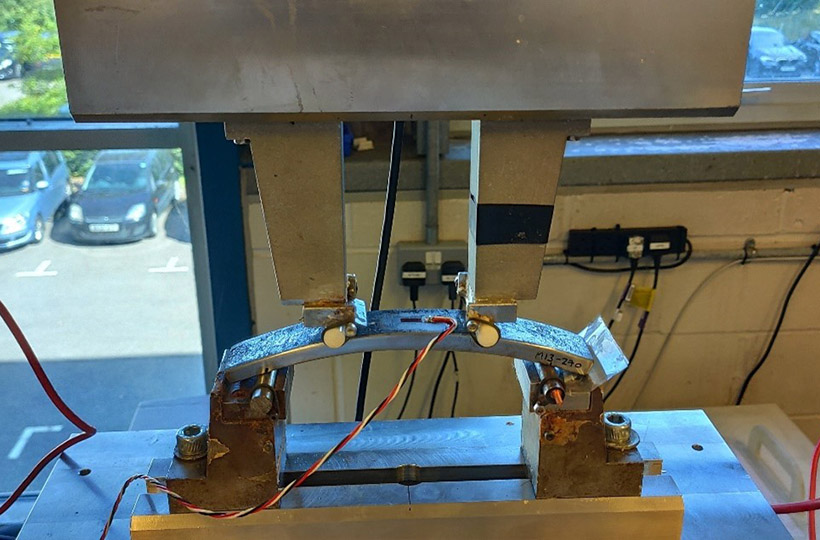

Comparative testing is being completed in inert gas and high-pressure, hydrogen gas. Testing includes tensile, toughness, and fatigue – key properties for pipeline design and safe operation. The image below shows a fatigue test in air on our material.

Fatigue Test of LTS Material

Figure 1 . Fatigue Test of LTS Material

Testing at DNV

At DNV, our hydrogen programme includes full-scale mechanical testing of pipe material, flowing gas tests and development of operational procedures. This included venting, flaring, live welding, under-pressure drilling (‘hot-tapping’) and flow stopping. See the below descriptions for further information on our full-scale hydrogen testing.

Burst and fatigue testing of pipeline defects has been completed for our blueprint report. These tests are used to evaluate the effect hydrogen has on pipeline defects and will feed into our future pipeline inspection procedures.

Venting and flaring tests were completed to develop operational procedures and define safe exclusion zones for pressure relief of hydrogen systems.

Performance testing of existing pressure reduction equipment will help us understand if existing equipment can be used with hydrogen, at current and higher flow rates. This may be required for future network scenarios due to the lower volumetric energy density of hydrogen.

Fatigue testing of small-bore connections has been completed to understand the fatigue life in hydrogen of instrument and branch connections.

Live hot works on a hydrogen flow loop allowed us to test and adapt existing procedures for safely making new connections on live hydrogen pipelines. This included installing new welded and grouted connection or diversion ‘tees’, drilling into the tees and isolating all whilst hydrogen is within the pipeline. The learning from these tests was to inform and develop safe procedures which were used in the live trial phase of our project. Currently there is no recognized industry standard or procedure for live welding or under-pressure drilling on hydrogen pipelines.

Figure 2: Flow-loop at DNV Spadeadam for hot works test program {image provided by DNV Spadeadam]

Figure 2: Flow-loop at DNV Spadeadam for hot works test program {image provided by DNV Spadeadam]

Figure 3: Split-tee welding at DNV Spadeadam {image provided by DNV Spadeadam]