The third generation of an innovative excavation and reinstatement fleet supporting gas network maintenance has reached UK roads.

Our Core & Vac Mk3 vehicles will revolutionise emergency gas pipe repairs by reducing environmental impact, increasing safety and efficiency, and providing cost savings for stakeholders.

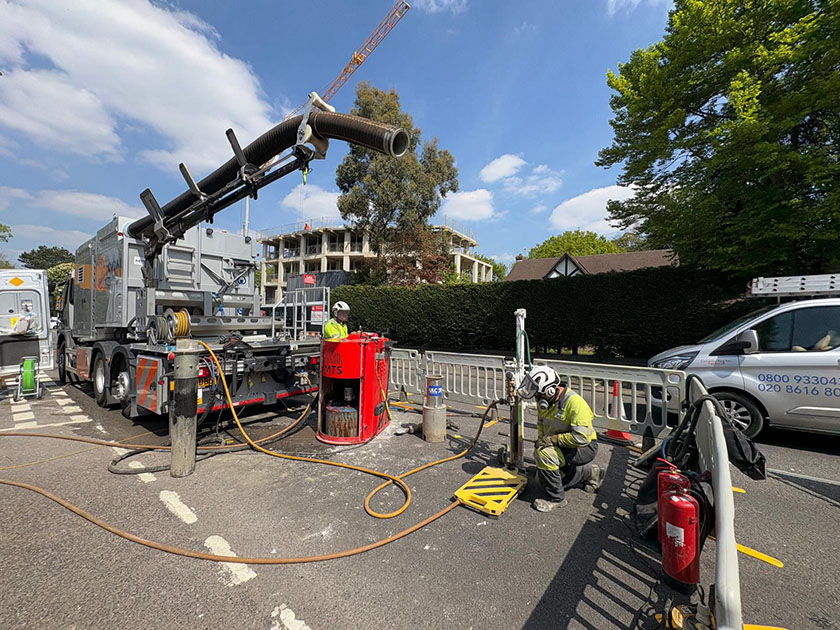

The latest model, developed in partnership with MTS, has a refined design to enhance speed, manoeuvrability and effectiveness compared with its predecessors. The Mk3 range builds upon the concept of vacuum excavation, enhances precision by allowing keyhole removal and reinstatement, and recycles excavated materials to realise a full circular economy benefit.

Core & Vac history

Core & Vac Mk1

Mk1 introduced the concept of vacuum excavation. It set out to reduce manual digging and improve safety.

Core & Vac Mk2

Mk2 enhanced precision and efficiency. It focused on enabling faster core removal and reinstatement by reducing disruptive aborted cores.

Core & Vac Mk3

Mk3 delivers 24/7 operability and a full circular economy benefit. It enables excavated materials to be recycled, cutting waste from our operations.

Four of these vehicles are on now on the road following a £1.3 million investment to ensure we deliver on our commitment to sustainability and efficiency as we maintain our gas network.

The technological advancements on the Mk3 mean reinstatement costs are reduced effectively to zero, while thousands will also be saved from lane rental costs thanks to the speed we can now work at. With a standard eight-year HGV expected lifespan planned for each vehicle, the fleet will pay for itself within a couple of years.

Joint repairs, service relays, camera surveys, main sprays, new supplies and repair clamp fitting are among the types of operations which can be carried out using our the Mk3. We can excavate with precision at 600mm width to reach our pipes, and depending on the road thickness and ground type, we can complete a keyhole excavation within 30 minutes. Using vacuum excavation reduces the risk of damaging other utilities located underground.

The launch of the next-generation of Core & Vac vehicles is testament to our ongoing commitment to deliver sustainability and value for money while we work to keep everyone safe and warm.

Mk3 vehicles will significantly reduce the environmental impact of our gas network maintenance. Less CO2 emissions will be produced, less waste will go to landfill and less reinstatement materials are required.

We can now place extracted core, lifted from a road to access our pipe, seamlessly back into position after we've completed our network investigations and repairs. This reduces reinstatement time from three days to three hours, reducing lane rental costs for stakeholders and minimising disruption to road users affected by closures.

Richard Jeffries

Specials Ops Manager

Our engineers were using the Core & Vac Mk3 to help repair our network in Purley at the end of April

Core & Vac Mk3 is shortlisted for an award

Our Core & Vac Mk3 has been shortlisted for the Business Innovation Award at the prestigious IGEM Awards.

This category recognises organisations demonstrating an ongoing commitment to the research, development and use of new technologies to address challenges facing the gas industry.

The awards ceremony will be held in London on Thursday afternoon (8 May).

Good luck!