Policy Engineer Jennifer Stant (left) and Project Engineer Tilly Spice (right)

This week marks National Engineering Day and in celebration of this, we’re sharing the stories of our own engineers who are improving lives and shaping the world around us.

Tilly Spice is a Project Engineer for our Renewable Development team. Although her work focuses on Biomethane, her spare time is currently taken up studying for an Engineering degree through the Open University, sponsored by SGN.

Tilly joined us in 2014, working in Maintenance Projects for four years before moving to Diversions in Network Planning in 2018.

In Maintenance, she supported the project team and while this role wasn’t operational, Tilly says: “the team were brilliant at getting me involved in technical training – courses like High Pressure Connections, Introduction to Pipeline Corrosion, Construction and Cathodic Protection and The Management of Pre-Construction Health & Safety Information Gas.”

Tilly says she was good at maths at school but didn’t carry this on after leaving and before these courses had never have seen herself as an engineer.

She added: “I’ve been so lucky that I’ve always had amazing support from my managers and the teams around me, pushing me to grow and develop. I was introduced to other colleagues who’d done the Uni course and this was when I started to see it as a possibility for me.”

Three years into the course and some aspects have been more challenging than Tilly had expected. As well as advanced maths knowledge being required, the course was impacted by the pandemic, meaning the degree was delayed by a year and some parts had to be delivered virtually instead of being face-to-face as planned.

Earlier this year, Tilly moved into her current role in biomethane and is excited to be involved in renewable energy. She says: “It’s going to be such an important part of our future as a country. Whether it’s biomethane or hydrogen, I can definitely see myself staying in renewables development – it’s something I’m so interested in and that was a big reason I wanted to do the Engineering degree to begin with.”

Policy Engineer Jennifer Stant has been developing new procedures to keep our engineers safe, redefining the Safe Control of Operations (SCO) requirements for our hot works. Hot works are any activity or process that generates a source of ignition. We carry out this work around 1,500 times a year both on and near our network.

She was tasked with reviewing hot works procedures across the company and, where possible, come up with a strategy to streamline the process, allowing more productivity and preventing delays in carrying out tasks.

Each time hot works are planned, one of our Authorised Engineers (AEs) will visit the site to carry out a risk assessment and write a Permit to Work (PTW). PTWs for hot works can only be issued by one of our 46 AEs but as the permitry is split by pressure tiers, not all of them can cover all tiers.

The majority of the hot works carried out within SGN are incidental hot works such as fencing, carrying out repairs or reroofing nearby structures with low risk hot works falling just after that, and the smallest number of occurrences falling into the category being the highest risk.

For each task, Jennifer carried out research looking at previous permits and risk assessments alongside any reported near misses and incidents that had occurred for those tasks. She also spent time reviewing the training and subsequent competence given to each operative that would be involved in those tasks and the quality of that training.

Her research led to the conclusion that in many cases, the Competent Person (CP) who has been issued a permit for the works already had the knowledge and expertise to carry out their own risk assessment and do the job at hand without needing to escalate to an AE.

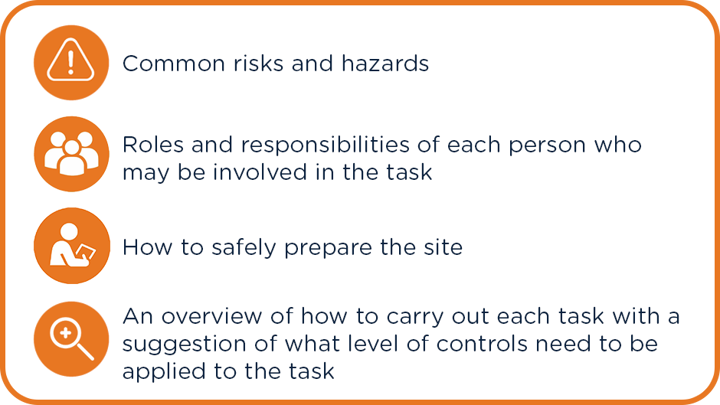

With this in mind, Jennifer drafted a guidance document outlining basic principles of each hot works task that could be carried out on the network including:

Jennifer said: “Based on the research I’d done, I came up with a range of changes to our current hot works procedures and presented the draft guidance document and works matrix to a group of engineers, CPs and AEs to gather feedback and ensure my conclusions were sound and that this was a credible solution. Based on the discussions that took place in that group, I fine-tuned the guidance document and the associated matrix.”

The guidance, checklist and written risk assessment means each job is individually assessed and has a recorded risk assessment associated with it proving a clear auditable trail. The structure of the checklist forces each task to be considered on its individual merits by the person responsible for the works and prevents complacency which may occur when visiting a site solely to write a permit.

Jennifer recently presented her work to the iGEM Young Persons Paper Competition’s London Region where she came a commendable second place. The proposed changes are currently being reviewed by our Head of Network Asset Management and once approved will become standard practice across the company.

Jennifer added: “This has been a really exciting project to be involved in with many benefits including safety improvements, increased productivity, increased experience and competency and ‘ownership’ of tasks.”

Both are keen to see more female engineers joining the industry and Tilly has some advice for women wanting to do an engineering degree:

- Dip your toe in before you commit. Talk to others who’ve done it or get involved in smaller courses like an NVQ (National Vocational Qualification) rather than diving straight into the degree. If you’re already working with us, try out some of the operational courses I was involved in to get a taste of what it’s like.

- Find out what support is available. If I hadn’t had supportive managers pushing me to be my best and giving me time off to accommodate the residential parts of the course, I can’t imagine how difficult it’d be to try to study alongside working. Getting the course paid for made all the difference too.

- Don’t be afraid. I realised when I started talking to others at the Open University that they came from all walks of life and it was reassuring to find I wasn’t alone in not having an engineering background!

Tilly added: “There are a lot of barriers for women going into engineering. In tutorial groups of 30 on my course, invariably 27 will be men.”

“I’m pleased SGN is setting up a new Women’s Network to help women in their career development and I’ve already signed up to be involved. I’m hoping that sharing my story might help other women start to see that a career in engineering is a possibility.”