Project Name: Hydrogen Consequence Testing

Project Lead: SGN

Partners: Kiwa Gastech Ltd

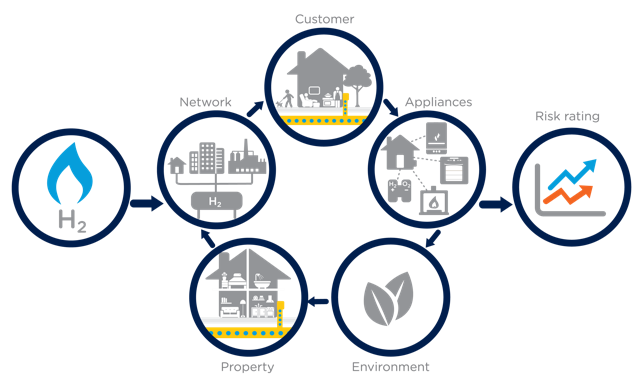

Our H100 Fife project included a Hydrogen Consequence Testing element. This element is comprised on four phases that study the impact of hydrogen on gas customer homes and investigates the risks associated with a hydrogen gas leak.

Phase 1

Phase 1 of this element investigated behaviours and consequences of hydrogen leakage into properties by conducting experimental and destructive testing. The results from the testing were then used to produce mathematical models and inform the H100 Quantified Risk Assessments (QRA) that compares the risks associated with natural gas and hydrogen. The QRA is used to satisfy the regulatory bodies that appropriate risk mitigation strategies are in place to reduce risk as low as reasonably practicable. The QRA will also help assess the current emergency process and its fitness for purpose for hydrogen distribution.

Phase 2

Phase 2 focused on methods to mitigate the risk of gas explosions associated with delayed ignition in boilers, fires and cookers and failures of gas meters, meter regulator diaphragms and pipework. The testing process was designed to address risks highlighted by an analysis from the Health and Safety Executive (HSE) incident data, which was gathered over five years.

The testing provides us with an understanding of what the worst-case scenario is for each appliance group and their potential for ignition and explosion. We can then use this to design safety systems to mitigate any risks identified.

Phase 3

Phase 3 tested the quantitative differences between natural gas and hydrogen in terms of size and duration of the pressure peaks. For this, a ‘shock tube’ instrument was used to replicate and direct blast waves at a sensor or model to simulate actual explosions and their effects. Shock tubes can also be used to study aerodynamic flow under a wide range of temperatures and pressures, which are challenging to obtain in other types of testing facilities, and to investigate compressible flow phenomena and gas phase combustion reactions.

The results from this testing can be used to quantify the relative overpressures generated by a series of different natural gas and hydrogen concentrations and these will be used assess the nature of the damage likely to be caused.

Phase 4

Phase 4 studied the odorant element of hydrogen distribution. Natural gas is injected with an odour to ensure any leaks are quickly detected. If similar odorants are to be adopted for hydrogen it will be necessary to confirm that they have the same level of effectiveness with hydrogen, as with natural gas.

The study investigated how long the odorant remains in hydrogen gas by tracking odorants with hydrogen to draw comparisons with existing methane use, in both movement and detection limits.